How the Alpha PdM System monitor the belt conveyor roller in Brazil?

ALPHA

Alpha has been committed to using our cloud PdM platform to achieve remote online monitoring of project sites around the world and intelligently analyze data. Use intelligent predictive maintenance strategies to ensure safe and efficient production on site. Alpha can not only produce our own wireless vibration&temperature sensor, wireless LoRa temperature sensor, meanwhile, we are integrating almost all kinds of sensors available in market, like current, noise, liquid level, etc.

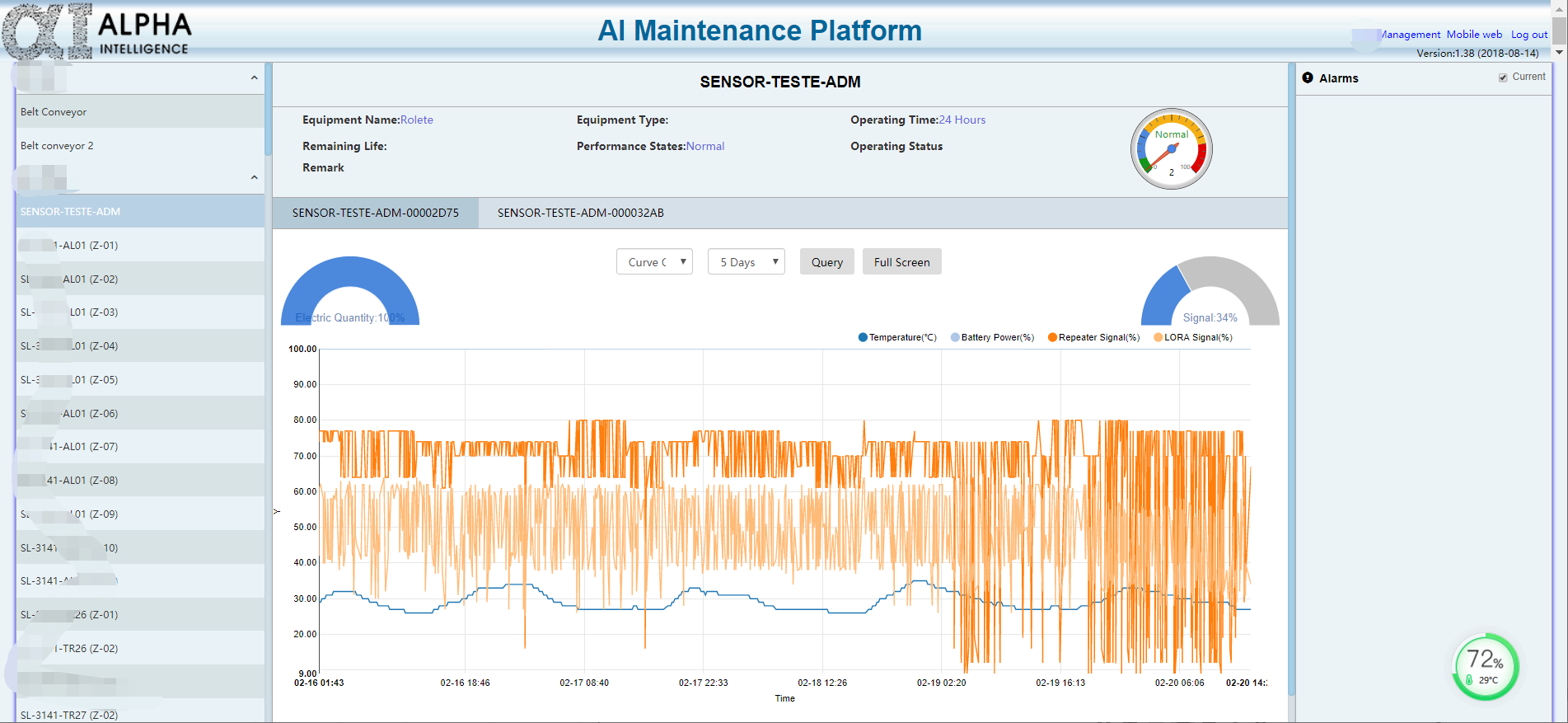

Cloud Platform Home Page(For reference)

In 2019, ALPHA team has completed the whole project process including the delivery, installation &commissioning on-site guide and training, also keeping proving the after-sales service all the time.

Here is a simple process explanation for how we do the belt conveyor temperature monitoring in Brazil, VLI Logística, a VALE company.

1.Installation and Commissioning

AT001wireless LoRa Temperature is installed on site roller, and the AJ002 4G repeater is wall mounted which can receive 500 sensors’ data at most.

2.Monitoring and Transmission

The sensors monitoring the roller, and transmits the real-time temperature data to gateway every several minutes(Can be set according to actual needs). Once the gateway receive the data, it will transmits data to Cloud Platform Via 4G. All the data will form data spectrum, like below picture:

3.Cloud Intelligent Analysis and Alarm

The Cloud embedded algorithm will analyze the data trend and give prediction, when there’s predicted alarm, it will be sent via email or WeChat Platform. Meanwhile, client can set the different alarm level according to different value.

Like for VLI, (Pre-Alarm)45-50℃, Alarm(50-70℃), Serious Alarm(>70℃).

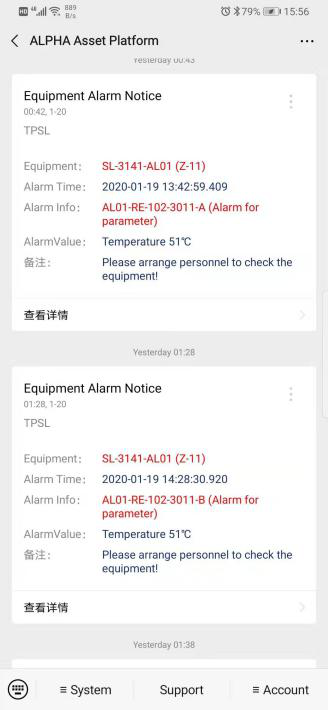

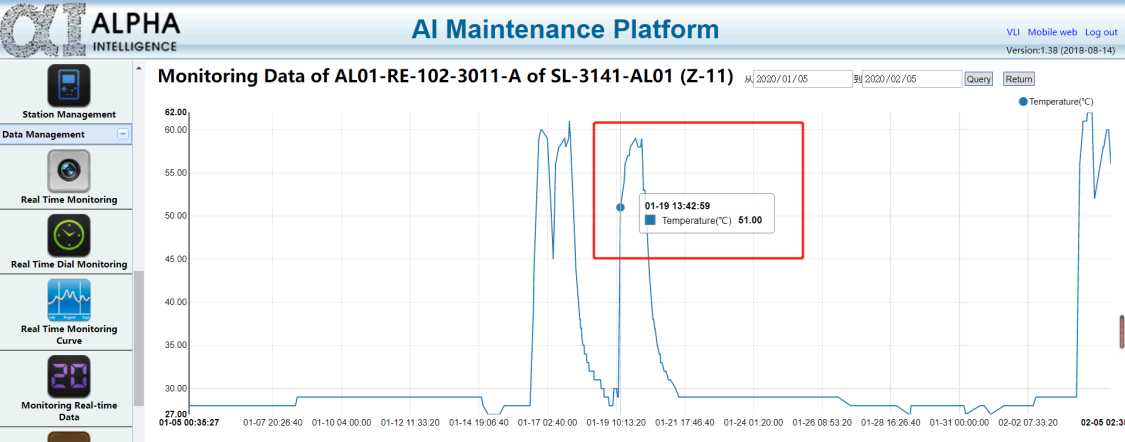

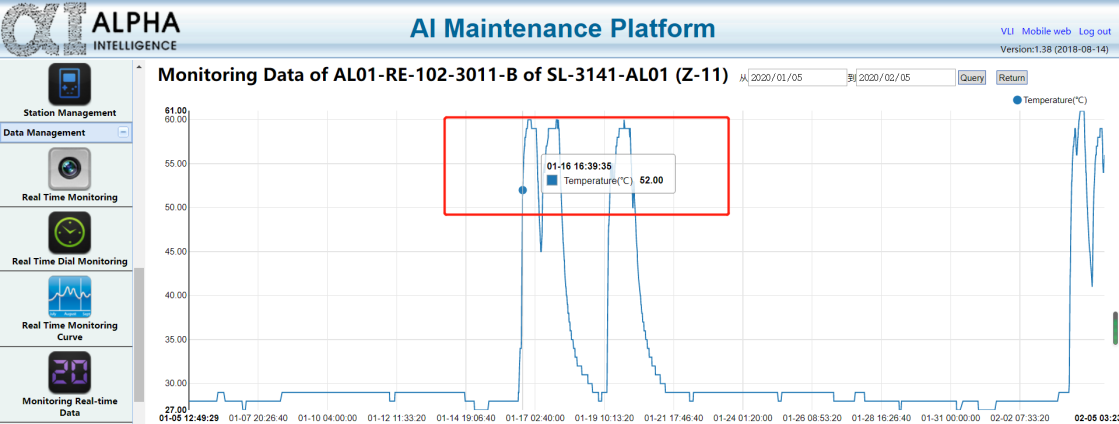

1) The Alarm from sensors (AL01-RE-102-3011-A, AL01-RE-102-3011-B)

The Wechat Alarm from two sensors.(AL01-RE-102-3011-A, AL01-RE-102-3011-B)

Check the data curve, there’s data is above the 50°C for the from the two sensors. From the data curve, we can see that it is not always the high temperature, we think it is during the belt running. The usual temperature is close to environment temperature, which may mean that belt conveyor is not under normal running.

Then the field personnel may need to pay more attention to the operation of these rollers.

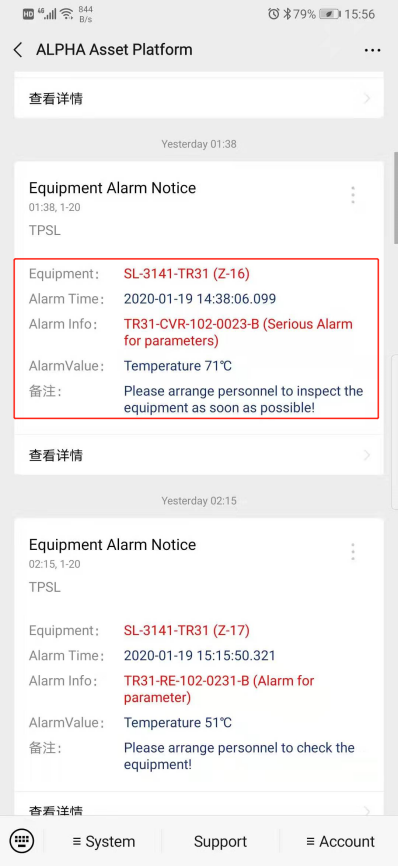

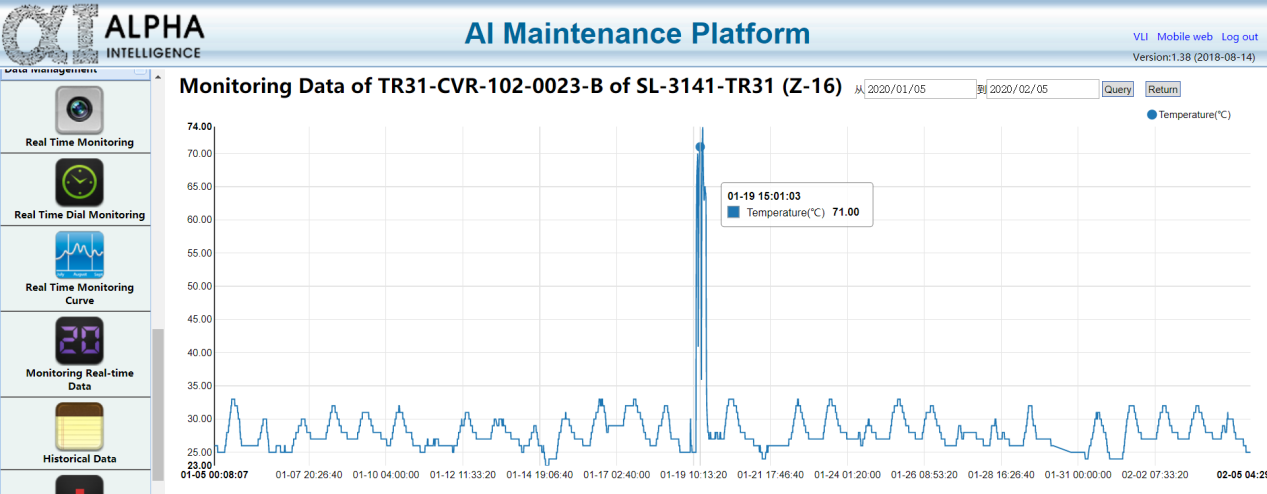

2) Serious Alarm from sensor(TR31-CVR-102-0023-B)

The Wechat seruous Alarm from the sensor( TR31-CVR-102-0023-B)

Checked the data curve of this sensor, during the normal running of the belt conveyor, the data curve is gentle and regular. Only during that time, there is sudden high temperature. We also think there may be some abnormal running status during alarm time.

About this kind of sudden high temperature, we suggest that the site personnel go to target sensor to check the running condition.

Every day, there will be daily report for every day running status, which to be cared more and which needs the maintenance. Then the site personnel can schedule the maintenance accordingly.

For more about ALPHA PdM strategy, sensors more than temperature, vibration, current, noise solution.