Predictive maintenance, how annually save the company millions of dollars?

Alpha Ind. Tech.

Predictive maintenance, how annually save the company millions of dollars?

Introduction

What`s the concept of predictive maintenance, and how it can replace preventive maintenance and avoid remedial maintenance, saving the company millions of dollars each year?

The car with “sickness” will bring security threats to traffic; the production equipment working with “sickness” will bring huge losses to the factory. For example, Intel's production line in Dalian creates a value of 150 million yuan every day. Even if it is down for 1 hour, the losses will be unbearable. Therefore, it is especially important to prevent equipment from mechanical breakdown.

Several kinds of means of maintenance and repair of industrial equipment

Corrective maintenance: belongs to the post-maintenance. It is the worst decision (If the plant equipment suddenly fails, stop working and repair the equipment)

Preventive maintenance: belongs to the pre-maintenance. Based on time, performance and other conditions of the equipment for regular maintenance, more depends on experience. It is always the better way to plan ahead. (such as regular equipment maintenance of the factory, maintenance of spare parts, etc.)

Predictive maintenance: belongs to the pre-maintenance, based on various sensors installed on the device, running real-time monitoring equipment, if you find hidden faults, automatically trigger warning or repair orders and making plans. It is the best policy. (If real-time monitoring gives the judgment of the abnormal operating state of the equipment during the operation of the equipment. Repair plan, targeted maintenance will be processed)

A more intuitive example of preventive maintenance: the first maintenance (replacement of oil) after 3000 km of the new car, regular cleaning of the production equipment, replacement of damaged parts, etc.

Predictive maintenance is the use of various means to collect data and signals (either intermittently or continuously), analyze and judge the deterioration trend of equipment, fault locations, causes and predict changes, and propose preventive measures. Prevent and control the occurrence of possible faults.

Monitoring sensor and data intelligent analysis software

sensor

The monitoring sensor is an edge device, which contains various electronic devices connected to the network terminal, such as gateway and camera. It is based on IoT's equipment that monitors, processes, and transmits the data. With such a small sensor device, it is stable to monitor the temperature and vibration data of the device through a small internal chip in real time.

Sensor chip

Data Intelligence Analysis Software (and Alpha Cloud Platform)

The data is collected by the sensor, processed and transmitted to the local database, and the data is uploaded to the Alpha Cloud through the network for continuous deep data comparison. Through the self-learning function of the software, the normal running state of each device and the abnormal running data under the wrong operation are continuously learned, thereby alerting the operation of the abnormal state of the device. Through historical maintenance records, spare parts replacement records and other data, the corresponding maintenance plan and reference solution are given.

Cloud platform analysis

Industry application

Intel

Intel's extensive deployment of the IoT brings more computing power to edge intelligence and has laid the foundation for predictive maintenance decades ago. Intel has implemented a predictive maintenance system in its own Fab plant, reducing cooling water consumption by 40%.

Honeywell

Honeywell launched GoDirect, a predictive maintenance service for connected auxiliary power units (APUs). Based on this service, airlines can detect and anticipate mechanical failures before they occur, improving fleet availability. Hainan Airlines became the first airline in the world to adopt GoDirect.

Bosch

In the history of more than 100 years of development, Bosch has always been known for its industry and manufacturing, and now Bosch is actively shifting towards interconnection and service. Bosch adds awareness devices to its devices to enable it to collect data. After that, the data will be transmitted to the Bosch IoT Cloud platform, and the data will be calculated and optimized by software to form the corresponding service.

Bosch is equipped with a full range of smart technologies in more than 250 plants around the world. AR technology enables workers to get assistance in real time, complete equipment maintenance tasks, and reduce downtime. Predictive maintenance is combined with the application of sensors to proactively predict failures and alert them.

Industry data for predictive maintenance

The biggest advantage of applying predictive maintenance is the reduction in overall cost. A study conducted by the US Federal Energy Management Program (FEMP) estimates that a properly functioning predictive maintenance program can provide 30% to 40% savings compared to preventive maintenance. According to relevant statistics, on average, the implementation of an industrial predictive maintenance program can bring about the following savings:

Return on investment: 10 times

Reduced maintenance costs: 25% to 30%

Fault elimination: 70% to 75%

Short downtime: 35% to 45%

Increase in production: 20% to 25%

At present, more than 80% of the equipment has not adopted an effective predictive maintenance program, and the cost of equipment maintenance exceeds 50% of the total life cycle cost of the equipment. According to the latest market report of IoT Analytics in 2017, the CAGR of predictive maintenance in 2016-2022 is 39%, and the total expenditure will reach 1.096 billion by 2022.

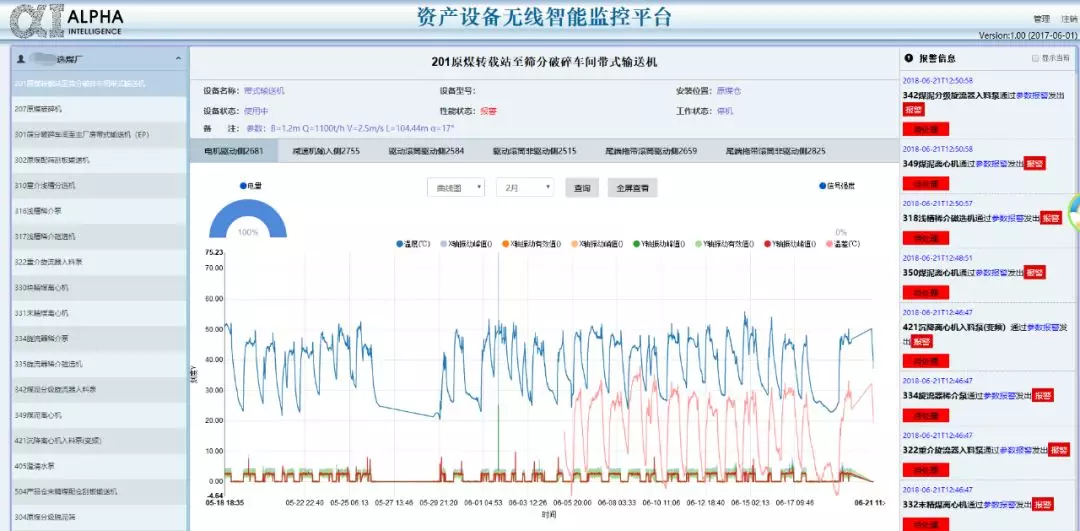

Alpha monitors and analyzes thousands of data from sensors every day, involving assets worth close to one hundred million yuan. The Alpha Cloud Industrial IoT Big Data Analytics Cloud Platform helps customers turn massive amounts of data into accurate decisions, ensuring timely, proactive asset security, helping equipment to run better, consuming fewer spare parts, and deploying services more efficiently. And minimize unplanned downtime.

In conclusion

Predictive maintenance of equipment will set off a revolution, from remedial maintenance, preventive maintenance to predictive maintenance has become a trilogy of industrial management. From the networking of devices, the IoT cloud platform is connected to sensors and software to achieve effective connection with each other, so that all core equipment in the factory can be monitored, managed and used more effectively. The prototype has just formed.

For more information about Alpha's intelligent service cooperation, please contact us.